Our Customers

We work with a variety of customers in the food, retail and medical markets across North America and globally. Each customer is very important to us as we value our long-lasting customer relationships and is a key reason we are here today. Our customers are always welcome to visit any of our locations to tour the facilities or to see their products manufactured in our production and clean room areas. Our headquarters in Madison, WI offers customers a unique experience where they can visit our Design Center of Excellence. This space was created to provide an open concept space with product display areas and technology to inspire new ideas, conduct project reviews and work together.

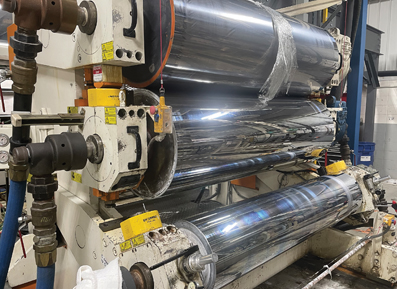

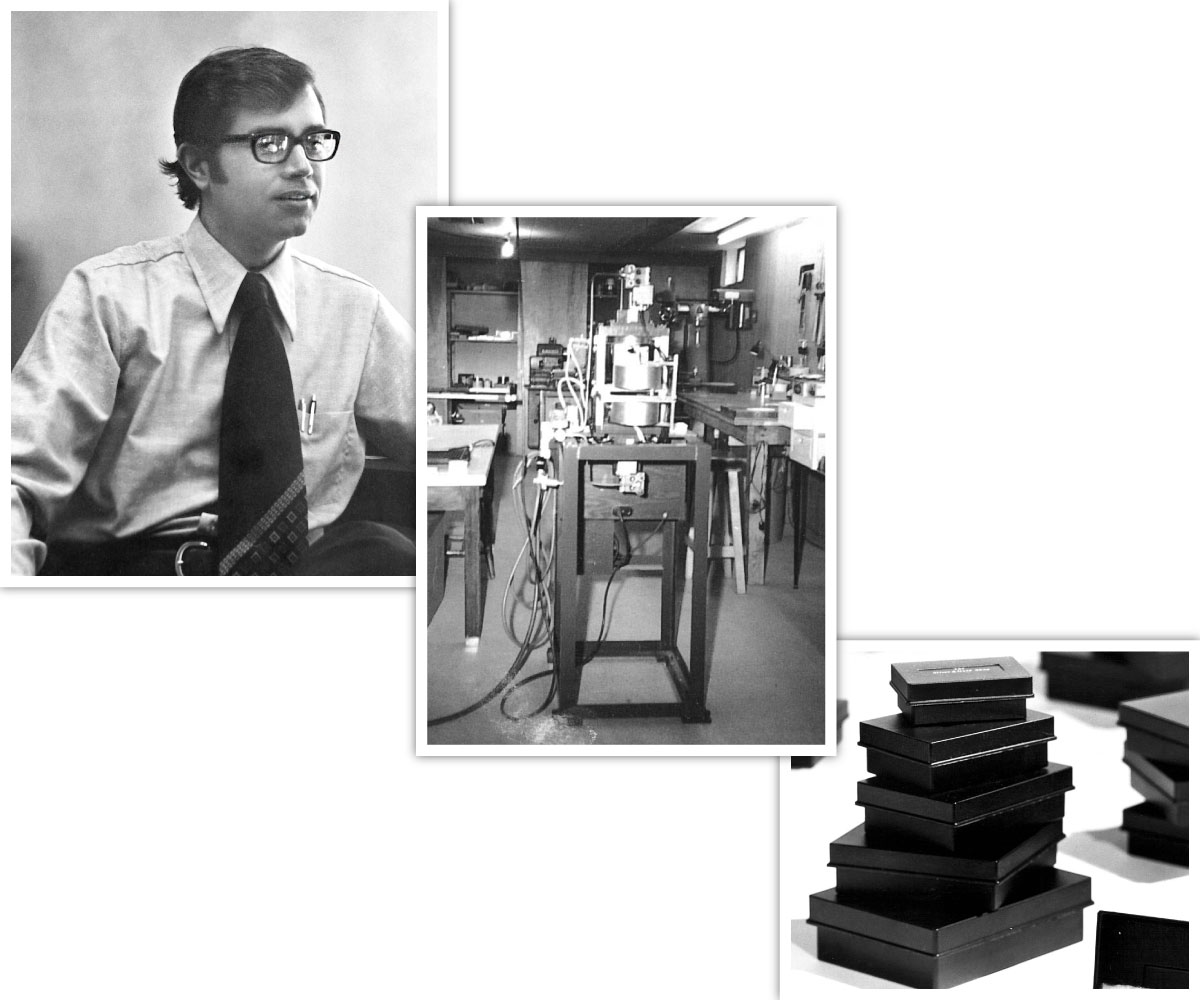

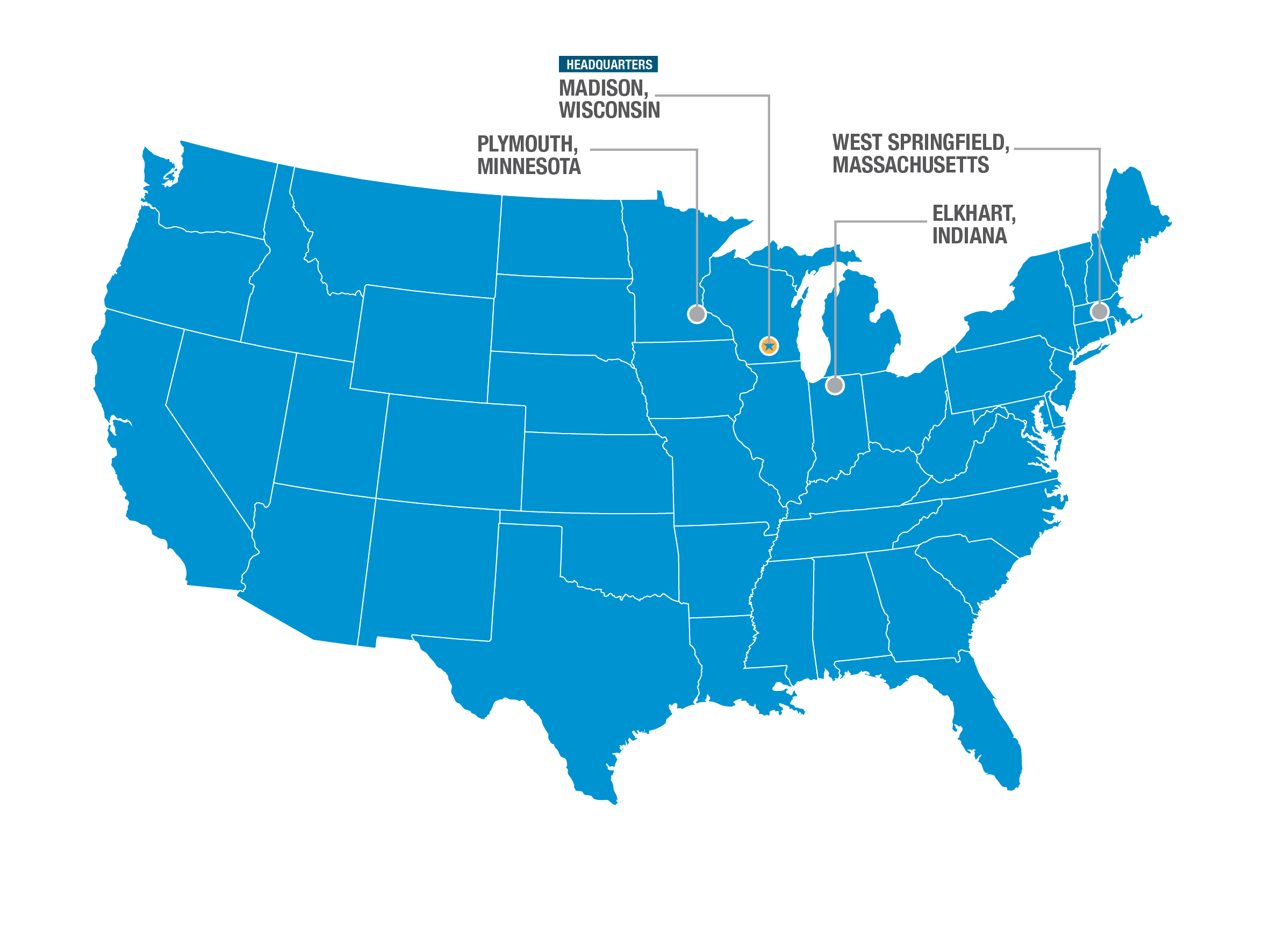

Our FacilitiesSince 1966, our headquarters has been in the great city of Madison, Wisconsin. It is here where our 340,000 square foot corporate facility houses a robust CNC machining department, world-class inline and rollfed thermoformers, extruders, state-of-the-art robotics and ISO 8 clean rooms. In addition, Madison is home to our state-of-the-art onsite recycling center where we bring in millions of recycled PET bottles and thermoforms each day to be processed into our EcoStar® post-consumer recycled PET material used in our food, medical and retail packaging. As we continue to grow and expand our business, it is essential that we have strategic manufacturing and warehouse locations across North America in order to assist and better service our customers with their day-to-day supply chain needs. Our other manufacturing locations include:

• Plymouth, MN

• West Springfield, MA |

We adhere to the high standards of safety, quality and sustainability required by the food, retail and medical packaging markets throughout each of our facilities. As a manufacturer of stock and custom food, retail and medical packaging along with using recycled post-consumer PET, it is important that we maintain our annual audits to ensure all specifications are upheld to meet our customer’s expectations. Each location goes through an individual audit depending on the products produced within that specific facility such as ISO 9001, ISO 13485, SQF and ISO Class 100,000 clean room certifications. You can find all of our certifications on our Resources page, which is found at the top of our website or in the footer area.